TECHNICAL REPORT 2

FOUNDATION

Introduction

Foundations provide support for

structures, transferring their load to layers of soil or

rock that have sufficient bearing capacity and suitable

settlement characteristics to support them.

There are a very wide range of

foundation types suitable for different applications, depending on

considerations such as:

- The nature of the load requiring support.

- Ground conditions.

- The presence of water.

- Space.

- Accessibility.

- Sensitivity to noise and vibration.

Very broadly, foundations can

be categorized as shallow foundations or deep foundations.

- Shallow foundations are typically used where the loads imposed by a structure are low relative to the bearing capacity of the surface soils.

- Deep foundations are necessary where the bearing capacity of the surface soils is not adequate to support the loads imposed by a structure and so those loads need to be transferred to deeper layers with higher bearing capacity.

Types of deep foundations

1.

Strip foundation (or footings)

Strip foundations are a type of

shallow foundation that are used to provide a continuous, level (or sometimes

stepped) strip of support to a linear structure such as a wall or

closely-spaced rows of columns built centrally above them.

Strip foundations can be used for

most subsoils, but are most suitable for soil which is of relatively good

bearing capacity. They are particularly suited to light structural loadings

such as those found in many low-to-medium rise domestic buildings - where mass

concrete strip foundations can be used. In other situations, reinforced

concrete may be required.

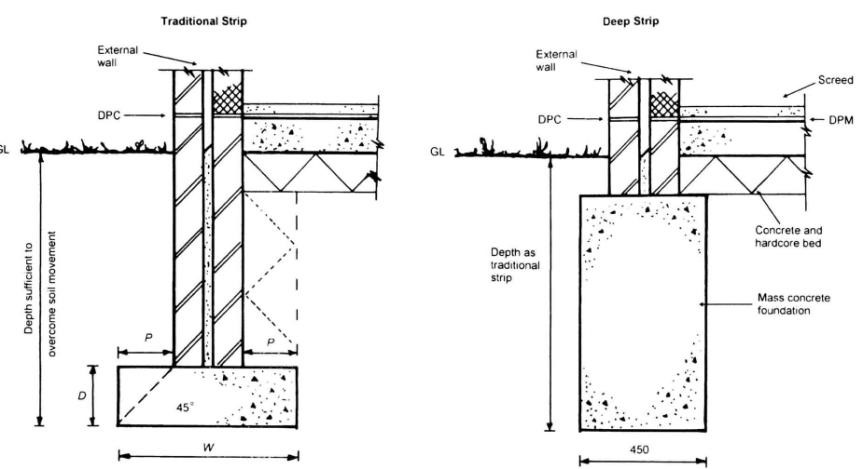

Generally, the size and position of

strip foundations is typically related to the wall’s overall width. The depth a

traditional strip foundation is generally equal to or greater than the overall

wall width, and the foundation width is generally three times the width of the

supported wall. This results in the load being transmitted at 45º from the wall

base to the soil.

The underside of strip foundations

should be deep enough to avoid frost action; for example, at least 450 mm

unless they are bearing on rock, and at least 1 m on high shrinkage clays.

Deep strip foundations may be

necessary where soil with a suitable bearing capacity is deeper.

Wide strip foundations may be

required where the soil is soft or of a low bearing capacity, so as to spread

the load over a larger area. Wide strip foundations will typically require

reinforcement.

2.

Pad foundations

Pad foundations are generally

shallow foundations, but can be deep depending on the ground conditions. They

are a form of spread foundation formed by rectangular, square, or sometimes

circular concrete ‘pads’ that support localised single-point loads such as

structural columns, groups of columns or framed structures. This load is then

spread by the pad to the bearing layer of soil or rock below. Pad foundations

can also be used to support ground beams.

They are generally of a uniform

thickness, but sometimes the upper face may be sloped or stepped. Their plan

shape will depend on the nature of the applied load and the allowable bearing

capacity of the layers below. Their thickness must be sufficient to distribute

the load across the plan shape. They are generally reinforced on all but the

smallest structures, with the reinforcement allowing higher loads to be imposed

and the construction of shallower pads which require less excavation and use

less concrete.

The arrangement of pad foundations

will vary depending on the nature of the structure they are supporting, the

loads imposed, the allowable bearing capacity of the layers below and the space

available on site. They may be:

a. Plain

concrete

Plain concrete pad foundations that

do not use reinforcement are an economical solution but only where the applied

load will be relatively light. These can also be referred to as footings. The

general rule is that the depth of the pad should be equal to the distance from

the face of the vertical element to the edge of the pad on both sides.

Pad foundations can be selected as

they do not require much excavation, and are generally suitable where the

bearing capacity of ground is sufficient at relatively low depths. However,

they can be large in plan shape and may not be effective against differential

settlement, uplift forces or wind forces.

Example of a plain concrete foundation.

b. Reinforced

concrete

The addition of reinforcement allows

for relatively wide but shallow pad foundations. In order to make the

reinforcing cage easier to construct and place, the pads tend to be designed as

a square plan area. The reinforced concrete base is designed to span in one

direction, with the main bars longitudinal in the bottom.

Where the width of the base is

restricted or where there is eccentric/inclined loading, rectangular pads can

be designed.

Reinforced concrete foundation built at site.

c. Combined column foundation

These are where two pad foundations

are combined into a longer one and can be used where the outer column is close

to a site boundary or existing wall. The purpose is that the balancing effect

of the internal column can be incorporated. The plan shape is usually a

rectangle.

Combined column foundation built at site.

d. Continuous pad

This is where the pad foundations

are combined together as a single long structural element. This is often the

case where the pads and the columns they support are closely spaced. By

extending the reinforcement between the pads, differential settlement can be

resisted and longitudinal stiffness can be improved.

e. Pad and ground beam

This is similar to a continuous pad

but differs in that smaller isolated pads are connected by ground beams. This

helps to improve structural rigidity.

Pad foundation and ground beam for boiler at 55MW power plant project.

3.

Raft foundations

Raft foundations (sometimes referred

to as raft footings or mat foundations) are formed by reinforced concrete slabs

of uniform thickness (typically 150 mm to 300 mm) that cover a wide area, often

the entire footprint of a building. They spread the load imposed by a number of

columns or walls over the area of foundation, and can be considered to ‘float’

on the ground as a raft floats on water.

They are suitable where:

- Floor areas are small and structural loadings are low, such as in one or two-storey domestic construction.

- A basement is required.

- Ground conditions are poor and strip or pad foundations would require significant excavation, for example on soft clay, alluvial deposits, compressible fill, and so on.

- Settlement, or differential settlement is likely.

- Where it may be impractical to create individual strip or pad foundations for a large number of individual loads. In very general terms, if strip or pad foundations would cover 50% or more of the floor area, then a raft may be more appropriate.

Raft foundations can be fast and

inexpensive to construct, as they tend not to require deep excavations compared

to strip or pad foundations and they may use less material as they combine the

foundation with the ground slab. However, they tend to be less effective where

structural loads are focused on in a few concentrated areas, and they can be

prone to erosion at their edges.

They are generally constructed on a

compacted hardcore base (perhaps 100 mm thick). A layer of blinding concrete

may then be laid to allow formation of the raft (typically 50 mm) with a

waterproof membrane above.

Types of raft foundation include:

- Solid slab raft, sometimes referred to as a plain raft, and including; flat rafts, mats, wide toe rafts, slip plane rafts, blanket rafts, and so on.

- Slab beam raft.

- Cellular raft.

- Piled raft.

The concrete raft tends to include

steel reinforcement to prevent cracking, and may incorporate stiffening beams

or thickened areas to provide additional support for specific loads, for

example, below internal walls or columns (which may require punching shear

reinforcement). Beams may stand proud of the raft, either above or below it, or

may be 'hidden' beams, formed by reinforced areas within the depth of the raft

itself. These thickened areas are particularly useful where there are poor

ground conditions, as the required thickness of the raft itself might otherwise

be uneconomic.

Typically, a thickened reinforced

area is created at the perimeter of the raft to form an edge beam supporting

the external walls of the building. A concrete toe often supports the external

leaf of the wall.

Steps to build a shallow foundation (example of reinforced pad foundation at site).

1. Excavation work for foundation at designated place. The volume excavated are normally bigger than the foundation appropiately.

2. A lean concrete is then poured onto the ground. The main function of the lean concrete is to provide a uniform surface for foundation and to prevent the direct contact of foundation to the soil. Then, form work is installed after measuring work done.

3. Next, reinforcement work is carried out based on the design. Usually steel wire and welding work would be used for steel bars binding work.

4. Concreting work is carry out after the reinforcement work and form work installation work.

5. Lastly, the foundation concrete would left for curing work for 3 days. Normally the worker will watering the foundation for curing work.

Types of deep foundations

1.

Pile foundations

Pile foundations are deep

foundations. They are formed by long, slender, columnar elements typically made

from steel or reinforced concrete, or sometimes timber. A foundation is

described as 'piled' when its depth is more than three times its breadth.

Pile foundations are principally

used to transfer the loads from superstructures, through weak, compressible

strata or water onto stronger, more compact, less compressible and stiffer soil

or rock at depth, increasing the effective size of a foundation and resisting

horizontal loads. They are typically used for large structures, and in

situations where soil is not suitable to prevent excessive settlement.

Piles may be classified by their

basic design function (end-bearing, friction or a combination) or by their

method of construction (displacement (driven) or replacement (bored)).

End-bearing piles develop most of their friction at the toe of the pile,

bearing on a hard layer. The pile transmits load direct to firm strata, and

also receives lateral restraint from subsoil.

Friction (or floating) piles develop most of the pile-bearing capacity by shear stresses

along the sides of the pile, and are suitable where harder layers are too deep.

The pile transmits the load to surrounding soil by friction between the surface

of the pile and soil, which in effect lowers the bulb of pressure.

Driven (or displacement) piles are driven, jacked, vibrated or screwed into the ground,

displacing the material around the pile shaft outwards and downwards instead of

removing it. These piles are useful in offshore applications, are stable in

soft squeezing soils and can densify loose soil.

Bored (or replacement) piles remove spoil to form a hole for the pile which is poured in

situ. They are used primarily in cohesive subsoils for the formation of

friction piles and when forming pile foundations close to existing buildings.

They are more popular in urban areas as there is minimal vibration, they can be

used where headroom is limited, there is no risk of heave and where it may be

necessary to vary their length.

Screw piles have a helix near the pile toe so they can be screwed into

the ground. The process and concept is similar to screwing into wood.

Micropiles are used where access is restricted, for example

underpinning structures affected by settlement. They can be driven or screwed

into place. Micropiles can also be used in combination with other ground

modification techniques where complex site conditions and design specifications

are present.

Pile walls can be used to create permanent or temporary retaining

walls. They are formed by placing piles directly adjacent to one another. These

can be closely-spaced contiguous pile walls or interlocking secant pile walls;

which depending on the composition of the secondary intermediate piles can be

hard/soft, hard/firm or hard/hard secant walls. Sheet piles is one of the type

of pile walls which are commonly use in our country.

The selection of sheet piling is

dependent on factors, such as:

- The type of work, for example. whether it is permanent or temporary.

- Site conditions.

- The required depth of piles.

- The bending moments involved.

- The nature of the structure.

- The type of protection required.

A wide range of equipment is

available for piling, including:

- Percussion drivers: Hammers driven by steam, compressed air or diesel.

- Hydraulic drivers: Hydraulic rams push piles into the ground.

- Vibratory drivers: Piles are vibrated into the ground.

- Rotary augers: Used to screw replacement piles into the ground.

Steps to build a deep foundation (Example of a driven end bearing piles at site).

a. Pegging of pile points at site based on a designed pile point drawing plan.

b. Demobilization of piles at site. A lorry send a group of piles to site and a crane carry out the demobilization work of piles at suitable place near to the pile point.

c. Next, the piling machine started to carry a pile and drove the pile at the pegged point.

2. Diaphragm wall

A diaphragm wall is a structural

concrete wall constructed in a deep trench excavation, either cast in situ or

using precast concrete components. Diaphragms walls are often used on congested

sites, close to existing structures, where there is restricted headroom, or

where the excavation is of a depth that would otherwise require the removal of

much greater volumes of soil to provide stable battered slopes.

Diaphragm walls are suitable for

most subsoils and their installation generates only a small amount of vibration

and noise, which increases their suitability for works carried out close to

existing structures. In addition, floor slab connections and recessed formwork

can be incorporated into the walls.

The walls generally range in

thickness from 500 - 1,500 mm and can be excavated to depths of over 50 m.

Excavation is typically carried out using rope-suspended mechanical or

hydraulically-operated grabs. Specific ground conditions or greater depths may

require the use of hydromills – hydraulically-operated reverse circulation

trench cutters – to penetrate into hard rock by ‘cutting’ rather than

‘digging’. Hydromills can achieve depths of up to 80 m.

The excavation stability is

maintained by the use of a drilling fluid, usually a bentonite slurry. This is

a controlled mixture that has thixotropic properties, meaning that it exerts a

pressure in excess of the earth and hydrostatic pressures on the sides of the

excavation. The walls are constructed, using reinforced or unreinforced

concrete, in discrete panel lengths generally ranging between 2.5 - 7 m. Purpose-made

stop ends can be used to form the joints between adjacent panels, with a water

bar incorporated across the joints. More complicated arrangements such as ‘L’

or ‘T’-shaped panels can be constructed where additional bending moment

capacity or wall stiffness is required.

Precast concrete diaphragm walls

have the same advantages but are less flexible in terms of design. The units

are installed in a trench filled with a special mixture of bentonite and cement

with a retarder added to control the setting time. Ground anchors are used to

tie the panels or posts to the retained earth to provide stability.

The high cost of diaphragm walls can

make them uneconomic unless they can be incorporated into part of a building

structure. As such, they are suited for deep basements, underground car parks

and rail stations, tunnel approaches, underpasses, deep shafts for tunnel

ventilation, pumping stations, and so on.

3. Caisson

A caisson is a box-like structure

commonly used in civil engineering projects where work is being carried out in

areas submerged in water. Such projects might include:

- Bridge piers.

- Abutments in lakes and rivers.

- Break water and other shore protection works.

- Wharves and docks.

- Large water front structures.

Caissons differ from cofferdams in

that cofferdams are removed after completion of the work, whereas caissons are

built to remain in place as a part of the completed structure.

Caissons can be made of materials

including timber, steel, masonry and reinforced concrete, and may be

constructed onshore then floated to the required location, where they are sunk

into place, enabling access to the bed and excavation of foundations to the

required depth.

They are particularly suitable for

the construction of underwater foundations or where the water is deep, as they

are strong enough to withstand significant vertical and horizontal loads, as

well as lateral forces such as waves.

Box caisson

This is a watertight timber or

reinforced concrete box with a closed bottom and an open top. The caisson is

cast and cured on land and then sunk into place, or it can be rested on top of

a pile formation. Sand, concrete or gravel is used to weigh down and sink the

caisson. This is most suitable for areas where the bearing strata is reasonably

level and no excavation is required, although it is possible for some dredging

to further level the base if required to avoid the tilting of the caisson once

in place. This type of caisson is generally relatively economical but may not

be suitable if the bearing strata requires compacting and/or leveling.

Open caisson

This is a timber, steel or concrete

box that is open at both the bottom and the top. The walls are heavy and made

with sharp edges that facilitate the sinking process. There are three different

types of open caisson:

i. Single

wall

ii.

Cylindrical

iii. Open with dredging wells

Pneumatic caisson

Pneumatic caissons are closed at the

top but open at the bottom, with the water forced out using compressed air,

creating a working chamber which is airtight in order for excavation to be

carried out. This is suitable when it is not possible to excavate wet ground in

the open.

Although this method is suitable for

difficult locations, such as depths ranging from 25-40 m, it is a complex, slow

and expensive procedure.

Selection of Type of

Foundation

The selection of a particular type

of foundation is often based on a number of factors, such as:

1. Adequate depth

The foundation must have an adequate

depth to prevent frost damage. For such foundations as bridge piers, the depth

of the foundation must be sufficient to prevent undermining by scour.

2. Bearing capacity failure

The foundation must be safe against

a bearing capacity failure.

3. Settlement

The foundation must not settle to

such an extent that it damages the structure.

4. Quality

The foundation must be of adequate

quality so that it is not subjected to deterioration, such as from sulfate

attack.

5. Adequate strength

The foundation must be designed with

sufficient strength that it does not fracture or break apart under the applied

superstructure loads. The foundation must also be properly constructed in

conformance with the design specifications.

6. Adverse soil changes

The foundation must be able to

resist long-term adverse soil changes. An example is expansive soil, which

could expand or shrink causing movement of the foundation and damage to the

structure.

7. Seismic forces

The foundation must be able to

support the structure during an earthquake without excessive settlement or

lateral movement.

Based on an analysis of all of the

factors listed above, a specific type of foundation (i.e., shallow versus deep)

would be recommended by the geotechnical engineer.

Foundation Failures

Foundations provide the support and resistance of the loads of the structures above. They serve as structural systems that transfer loads to the soil below and that provide stability, including resistance to overturning, sliding, and uplift, for the overall structure. Due to the importance of their structural system to the overall structure, it is imperative that their structural integrity is maintained for the overall structure to function. However, in some cases, foundations can fail. We are now going to explore the different types of causes that can affect the failure of foundations, in order to prevent and remediate the failures.

Below are the causes of foundation

failures:

Uneven loading

The uneven distribution of loading

from the superstructure can induce uneven stresses at different locations of

the foundation. This can cause differential settlement at locations where

vertical structural elements, such as columns and walls, directly transfer the

superstructure loads to the foundation. Differential settlement can

eventually lead to cracks at the foundation.

Overloading

Overloading from the superstructure

can also create foundation failure. Foundations can fail by cracking when

the design moment and/or shear is above its moment and/or shear capacity.

Failure can also occur when there are large concentrated or point loads, which

can induce large punching shear onto the foundation, and when there is over

designing of bearing pressure.

Different properties of soil at the

foundation interface

Different parts of the foundation

can rest on different properties of soil. For example, one part of the

foundation can sit on clay, while another part of the foundation can sit on

rock. When all design checks are adequate for one part of the foundation due to

that part resting on good soil and when checks fail for another part of the

foundation due to bad soil properties at the other part of the foundation, the

whole foundation can fail.

Ground investigation will need to be

used to determine these different soil properties. The foundation

structure will need to be designed in consideration of the different soil

stiffness and soil properties.

Insufficient soil compaction

The soil fill underneath the

foundation might not be compacted properly and to its required degree of

compaction. Since the soil is not compacted properly, air voids can be created

within the soil, in which soil and water can displace in and out of. There will

then be movement within the soil, which causes swelling and contracting. The

swelling and contraction of the soil can cause pressure to the foundation that

the soil supports.

Air voids within the soil can cause

loose soil or soil with low density, which lacks adequate strength to support

the foundation. Poor compaction equipment can also lead to foundation failure.

Therefore, it is best to compact the

soil beneath the foundation to its required compaction degree before concrete

placement of the foundation, in order to reduce soil displacement, to increase

subgrade reaction and soil density, and to reduce differential and overall

settlement of the foundation.

Uneven moisture levels of soil

beneath the foundation

Similar to the above scenario,

uneven moisture levels of the soil can cause soil swelling and contraction at

specific parts of the foundation. This can lead to stress at intersecting

locations where the soil is swelling and contracting and where the soil is not.

Changes in moisture levels of soil

beneath the foundation

Moisture levels of the soil can change due to varying humidity levels, rainy weather, or poor drainage conditions, which can cause soil to swell (or heave) and contract, therefore leading to cracks. Similar to insufficient soil compaction, the voids within the soil can be filled up by water or other fluids, which can create pressure onto the soil particles from the fluid.

However, when there are dry periods, the water evaporates from the soil and leaves from the voids within the soil. This can cause soil shrinkage.

Moreover, when there are cracks within the foundation, water seepage can also occur.

Moisture levels of the soil can change due to varying humidity levels, rainy weather, or poor drainage conditions, which can cause soil to swell (or heave) and contract, therefore leading to cracks. Similar to insufficient soil compaction, the voids within the soil can be filled up by water or other fluids, which can create pressure onto the soil particles from the fluid.

However, when there are dry periods, the water evaporates from the soil and leaves from the voids within the soil. This can cause soil shrinkage.

Moreover, when there are cracks within the foundation, water seepage can also occur.

Vibration from adjacent construction

Vibration from nearby construction can displace soil particles underneath the foundation. This can then create air voids within the soil, which can loosen up the soil and lower the soil density. The lower the soil density, the lower the soil strength for the support of the foundation. This will then cause foundation failure.

Vibration from nearby construction can displace soil particles underneath the foundation. This can then create air voids within the soil, which can loosen up the soil and lower the soil density. The lower the soil density, the lower the soil strength for the support of the foundation. This will then cause foundation failure.

Transpiration

If there are trees adjacent to the foundation, the trees can evaporate the water from the soil into its roots and into the atmosphere. This can cause changes in the moisture level of the soil.

If there are trees adjacent to the foundation, the trees can evaporate the water from the soil into its roots and into the atmosphere. This can cause changes in the moisture level of the soil.

Conclusion

The foundation is the base and one of the most important part in the

construction of any building or structure. Foundation act as a main part to

carry the structure load above of it and transfer the load into the ground to

prevent the structure or building from collapse. The type of foundation must be

wisely chose and designed based on the type of soil at site to maximise its

function. To prevent the case of foundation failure, soil investigation work

must be carry out carefully.

this article is great because of that it contain a great information. and Strip Footing Foundation is a small family run business offering a professional and expert service of piling and groundwork throughout Essex, Hertfordshire and London.

ReplyDeleteContig Wall Piling is a reliable solution for creating robust and durable retaining walls in construction projects. At Alpha Piling LTD, we specialize in delivering high-quality contig wall piling services, ensuring stability and efficiency for your construction needs. Contact us today for expert piling solutions tailored to your requirements."

ReplyDeleteGreat technical report! The explanation of ground anchor systems is thorough and insightful. Bhagwati Machinery appreciates such detailed content that supports civil engineering professionals. Thanks for sharing!

ReplyDeleteinformation about foxtpax software is a platform/keyword focused on smart learning, study tips, and educational resources for students.

ReplyDelete